Zero Waste Production from a Zero Waste Tree. What does this mean?

The ultimate goal of zero waste production is to develop and promote a more circular economy through the (re)design of products to reduce their environmental impact, designing waste out of the loop before consumers have to deal with it.

Zero waste manufacturing or production is a challenging prospect.

Linear production methods that prize profit over sustainability are everywhere—from the prevalence of single-use plastics in packaging to the fast fashion industry, this is how businesses have been built for as long as we can remember.

So how do we change this? How can we reduce waste materials before they enter the consumer market?Which is the key to achieving zero waste to landfill.

Zero waste production is the movement to implement more sustainable practices across the entire production and supply chain. This doesn’t mean only removing waste at the point of production, but thinking instead about the entire life cycle of a product – from what waste is created when it is being made, to what happens to a it and its packaging once it’s “consumed” and disposed of by the customer.

So how do we approach this at Three By One?

In 2015 we started with just one single product, our Organic Virgin Coconut Oil. While spending time with our producers I soon realised that there was some waste created while producing the oil. So I set about to see what I could use this waste for, and soon discovered that the coconut tree and its fruit could be considered a zero waste tree!

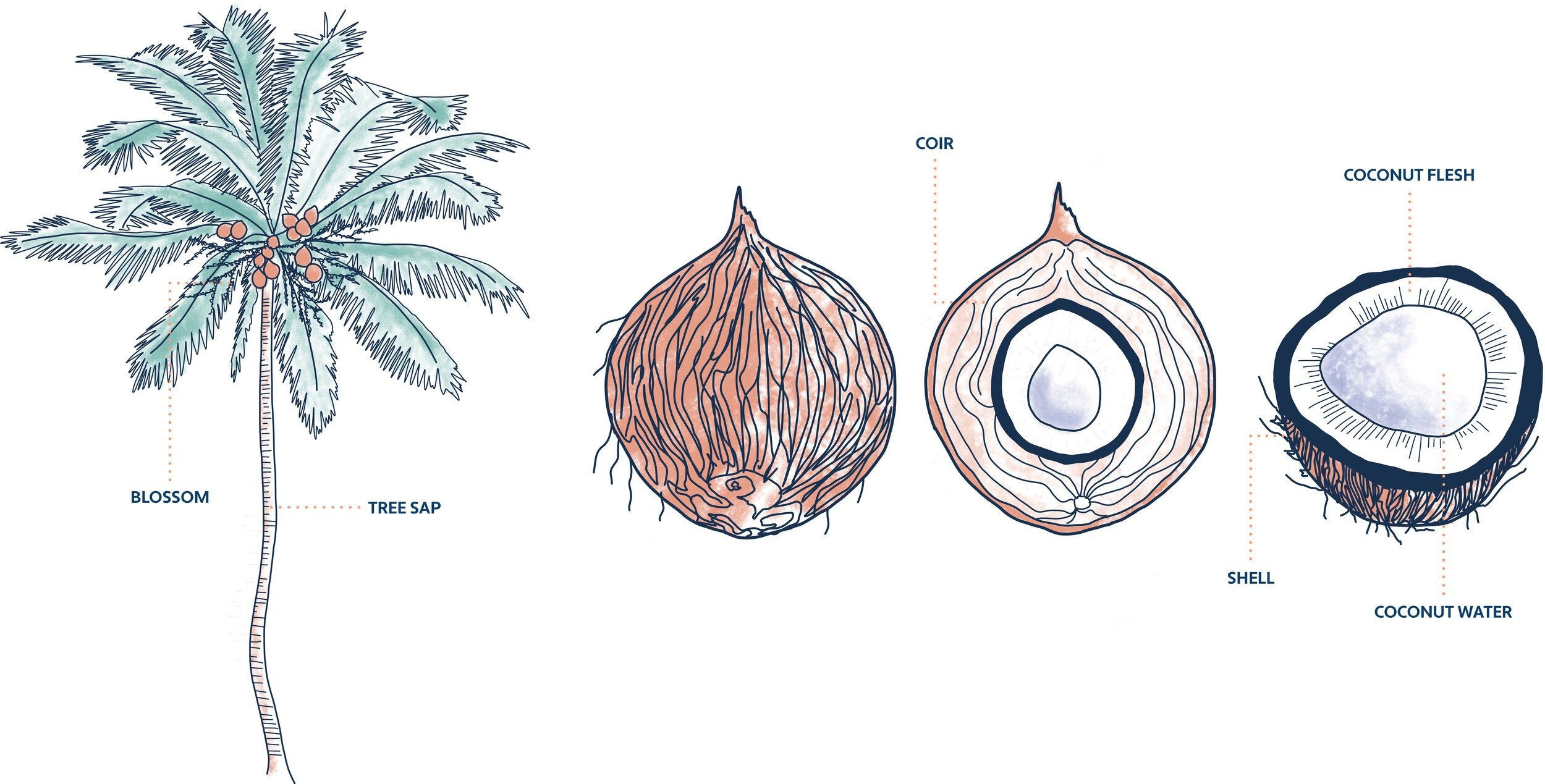

The Coconut tree is one of the best examples of a natural product which actually produces very little waste at all, as every part of the tree has a use. So as long as you use the ‘waste’ it can be considered zero waste!

When we make the Virgin Coconut Oil we are using the fruit of the tree only. The outer skin and husk is removed, the flesh is scraped from the inner shell, and the oil is pressed and extracted from the flesh. So there are several ‘waste’ products left over.

From the ‘waste’ flesh we create coconut jam, coconut cacao spread and coconut milk.

From the shells we create bowls and soap dishes. Any shell parts that are too small to make into these items gets turned into activated charcoal which we use in our cleansing bars.

From the discarded husks and skins we extract coir to make the sponges and scrubbers and we use the husk and skins to dye our textile products.

But that’s not all the parts of the tree that can be used.

The sap from the tree, once carefully harvested, is used to create coconut nectar and sugar, coconut cider vinegar and coconut aminos.

The wood of the trunk, once the tree is no longer alive, can be used as timber. It is often used for home construction, as beams, joists and frames for both windows and doors. It is also commonly used to make household items such as bowls, plates and spoons. It is even used to make jewellery.

And finally the leaves, known as fronds. A common use for palm fonds is as a roofing material. All over Sri Lanka you can see roofs made from coconut leaves. Coconut palm fonds can also be used for weaving mats.

Here at Three By One, our journey to absolute zero waste production is on-going. We are far from perfect! This philosophy is something we are constantly working on, thinking about, and evolving, along with our producers and partners. And hopefully also with you, our consumers, as you repurpose the empty jars, and compost old sponges. Every little bit helps.